morphology development and strain

The understanding and controlling the evolution of compound morphology in blending facilities where two or more immiscible polymers are blended is a long-term dream of researchers in polymer processing. In immiscible polymer blends, as a typical example of heterogeneous systems, the internal microscopic phase structure of the material directly affects the macroscopic end-use properties. Therefore, control of the morphology of these systems during processing can result in materials with balanced mechanical and / or barrier properties tailored to particular applications.

Research is concerned with the relationships between rheology and morphology development in immiscible polymer blends under strain deformation in the molten state. Although elongation is the dominant flow in many polymer processing technologies, there is not much data in the literature on polymer compositions under strain deformation. Together with the fact that the properties of immiscible polymer blends are clearly influenced by their phase structure, the investigation of morphology development in polymer blends under strain flow is of great interest. The investigation of the influence of the deformation conditions on the mixing behavior under strain flow is systematically investigated. In addition, the influence of various parameters characterizing the morphology of the mixtures on the mechanical properties of polymer blends is investigated.

The research has three main goals:

1. Investigation of morphology development in immiscible polymer blends during and after the stretch flow.

2. Investigation of the influence of compatibilizers on morphology development under elongation flow.

3. Investigation of the influence of concentration, size and shape of the dispersed particles on the mechanical properties of the mixture.

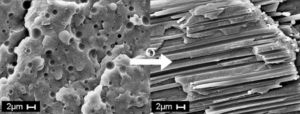

Picture 1: Morphology of a PS / LLDPE 90/10 blend before (left) and after (right) elongation (T = 170 ° C, σ = 20 kPa). The initially spherical LLDPE particles are deformed into highly elongated fibrils.